Swisslog recently won an order to deliver an innovative storage and order picking system for Siemens Mobility

The company, which is active in the areas of rail vehicles and rail automation solutions, will move into its new materials and spare parts warehouse in Wallisellen, Zurich in the coming months.

“We are incredibly pleased to announce Siemens Mobility AG has entrusted Swisslog to install an innovative AutoStore storage and picking system for small parts. With our agile local realization and service teams, we can implement the system for Siemens very quickly and efficiently,” commented Dr. Christian Baur, CEO, Swisslog.

With over 270 AutoStore projects worldwide, Swisslog is the leading provider of this solution. In Switzerland alone, there are over 30 Swisslog installations.

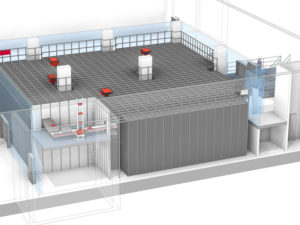

The main components of the automated logistics solution in Zurich include AutoStore storage system with 10,000 bins and 4 robots installed in the basement for optimal space utilization; ergonomic picking stations on the first floor with plenty of daylight for the operators; Tote conveyor technology in the basement, first floor and connecting tote lift and Swisslog SynQ software, which controls the entire automated solution.

“By separating the warehouse in the basement and the pick station on the first floor, we enable our colleagues to work in daylight, which is of course very important for their comfort,” noted Gerd Scheller, CEO, Siemens Mobility AG.